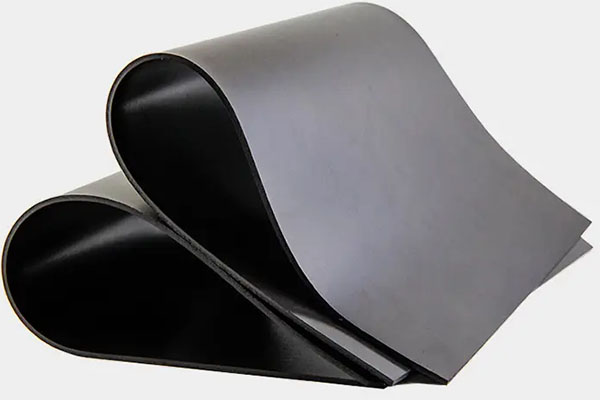

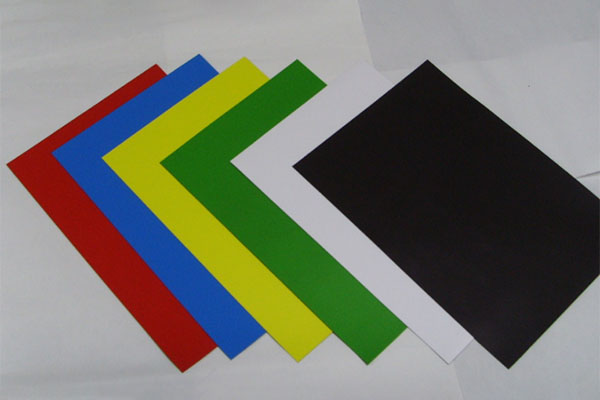

Kamora ho sebetsoa, sebopeho sea tenyetseha, se tenyetseha, 'me se ka kobeha, 'me sebopeho se ka fokotsoa ho latela boholo bo hlokahalang, hape se ka koaheloa ka PVC, sekhomaretsi le oli ea UV ho latela litlhoko tse ikhethileng tsa bareki.

Teko ea eona ea ts'ebetso ka kakaretso e kenyelletsa ponahalo, boholo, thepa ea makenete, polarity ea khoheli, ho thatafala, matla a khoheli a ikhethileng, matla a thata, ho hanyetsa botsofali, ts'ebetso ea ho potoloha.

Melemo ea eona e mabapi le ho tsitsa ha eona hantle, ho nepahala ha maemo a holimo;tšusumetso e ntle le ho hanyetsa ho sisinyeha, ha ho bonolo ho senya;matla a khoheli a nyenyane a loketseng ho bobebe ba sesebelisoa le mochine oohle;e ka etsoa makenete e nang le sebopeho se felletseng sa radial (mahlaseli a felletseng), 'me e ka hlahisoa ka libopeho tse fapaneng tsa makenete joalo ka libopeho tse telele le tse tšesaane, mme ha ts'ebetso ea morao-rao joalo ka ho koala, ho phunya, ho phunya le ho kobeha ho ka etsoa habonolo. .

Bothata ba eona ke hore magnetism e fokola haholo, 'me matla a khoheli a qala ho theoha ho 100 ° C, ntle le moo, makenete ea rabara e na le lintho tse ngata tsa tšepe tse kang neodymium le tšepe, tse tla senyeha le ho chesoa moeeng. litšoaneleho tsa mocheso li batla li fokola, 'me ho bonolo ho siloa.

E sebelisoa haholo ho litiiso tse Tight mamating a sehatsetsing, likhabinete tse bolaeang likokoana-hloko, likhabinete tsa kichineng, lintho tsa ho bapala, lintho tsa ho ngola, lipapatso, li-motor tse futhumatsang komporo, li-motors tsa phepelo ea moea, li-printer drive motors, VCD le li-DVD drive motors, brushless DC wind (e leketlileng. ) Fans, makenete Door seal, mekhabiso, materase a tlhokomelo ea bophelo bo botle ba makenete, lithupa tsa makenete Letšoao la nakoana la mokhanni oa likoloi tsa bapalami, Lits'oants'o tsa ho folisa li-lifti (ha e le hantle li-lifti kaofela li sebelisa lishiti tsa ho folisa), Sengoloa le thepa e ncha (e loketseng lintho tse amanang le sechaba).

Thepa ea 'Mele ea Magnet ea Rubber

| Thempereichara ea curie (℃) | 100 |

| Boholo ba mocheso o sebetsang (℃) | - 40-80 |

| Hv (MPa) | 33-38D |

| Density (g/cm3) | 3.6-3.8 |

Phallo ea Tlhahiso

Tlhahlobo ea Lintho

Ho Kopanya Lintho

Banburying

Ho pshatla

Extruded Molding

Tlhahlobo le Packaging

Lethathamo la ts'ebetso ea thepa ea makenete ea rabara

| Mohlala | Mofuta oa Sehlahisoa | Ts'ebetso ea Magnetic | Thepa ea 'Mele | ||||||||||

| Br | BHc | Hcj | BHmax | Matla a Tensile | Ho thatafala | Botenya | Temp. | ||||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m³ | MGO | kg/c㎡ | A | g/cm³ | ℃ | ||

| DMS001 | Isotropic extrusion magnetic strip | 140-180 | 1400-1800 | 105-130 | 1320-1635 | 160-238 | 2010-3000 | 4-6.4 | 0.5-0.8 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS002 | Semi-anisotropic extrusion magnetic | 180-210 | 1800-2100 | 130-151 | 1635-1900 | 175-286 | 2200-3600 | 6.4-8.8 | 0.8- 1. 1 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS003 | Isotropic colendering rabara makenete | 180-220 | 1800-2200 | 111- 143 | 1400-1800 | 143-191 | 1800-2400 | 5.6-8.8 | 0.7- 1. 1 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS004 | Anisotropic extrusion magnetic strip | 210-250 | 2100-2500 | 151- 179 | 1900-2250 | 191-319 | 2400-4000 | 8.8-12 | 1. 1- 1.5 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS005 | Semi-anisotropic colendering rabara makenete | 220-240 | 2200-2400 | 128- 151 | 1600-1900 | 159-207 | 2000-2600 | 8.8- 11.2 | 1. 1- 1.4 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS006 | Anisotropic colendering rabara | 240-270 | 2400-2700 | 151- 179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.6 | 1.4- 1.7 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS007 | Motlakase oa motlakase oa 500 # | 240-270 | 2400-2700 | 151- 179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.6 | 1.4- 1.7 | ≥15 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS008 | Motlakase oa motlakase oa 300 # | 240-265 | 2400-2650 | 151- 179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.2 | 1.4- 1.65 | ≥15 | ≥95 | 3.6-3.8 | -40 ~ 85 |

Pontšo ea Litšoantšo

-

Likopano tsa Magnet tse nang le NdFeB, SmCo, AlNiCo le ...

-

Thibela NdFeB, hangata e sebelisoa ho mototo o moleng ...

-

Round NdFeb, hangata e sebelisoa ho electroacou ...

-

Mefuta e meng ea NdFeB, joalo ka sebopeho sa bohobe, likoti-s...

-

Karolo ea NdFeB, hangata e sebelisoa ho motlakase ...

-

Ring NdFeB, hangata e sebelisoang ho sebuela-hōle