Re sebelisa foromo ea no-dysprosium ho lihlahisoa tsa boemo bo tlase bakeng sa bareki ho fokotsa litšenyehelo.Re na le foromo e tsitsitseng e ka etsoang lihlahisoa tse tlase tsa mocheso o tlase.E fokotsa litšenyehelo mme e eketsa ts'ebetso e eketsehileng bakeng sa bareki ba nang le taolo e tiileng ea ho mamella ts'ebetsong le ho roala ho ea ka litlhoko tse fapaneng tsa bareki ho netefatsa botsitso ba tšireletso ea plating ka nako e le 'ngoe, ho kenyelletsa le ho fafatsa letsoai, ho tlama matla, ho kopanya li-colloid joalo-joalo. .

Lihlahisoa tse pota-potileng li na le tšekamelo ea ho lahleheloa ke likhutlo nakong ea tlhahiso.Kahoo re na le lisebelisoa tsa tlhahlobo tse felletseng tsa ho mamella ponahalo, tse ka netefatsang bofokoli ba sehlahisoa ka har'a mefuta e laolehang le ho qoba lihlahisoa tse nang le phoso ha re sebelisa ts'ebetso.

Mabapi le ho feto-fetoha ha flux, re netefatsa hore sebōpi sa sintering se tsitsitseng se lumellana le taolo ea ts'ebetso ea makenete, le lisebelisoa tsa tlhahlobo tse felletseng tsa makenete ho thibela lihlahisoa tse fokolang tsa makenete hore li se ke tsa phallela ho bareki.Mabapi le sephutheloana sa magnetization, k'hamphani ea rona e na le lisebelisoa tsa othomathike tsa coding magnetization ho thibela basebetsi ho senya tefiso ea makenete.

Mabapi le taolo ea ho pepa, palo e kholo ea mechine e sehang e nang le mela e mengata, li-slicing units, basebetsi ba hōlileng tsebong ba sebetsang ka theknoloji, ts'ebetso e phethahetseng ea tlhahiso ea lihlahisoa, mohato o mong le o mong oa ts'ebetso ea lihlahisoa le tlhahiso e ka fumana maikutlo a tsoelo-pele ka nako leha e le efe, mohala oa tlhahiso ea lihlahisoa tsa cylindrical, ho netefatsa litlhoko tsa taolo ea bareki bakeng sa ho fana ka lihlahisoa, hammoho le tsoelo-pele e laolehang ea tlhahiso.

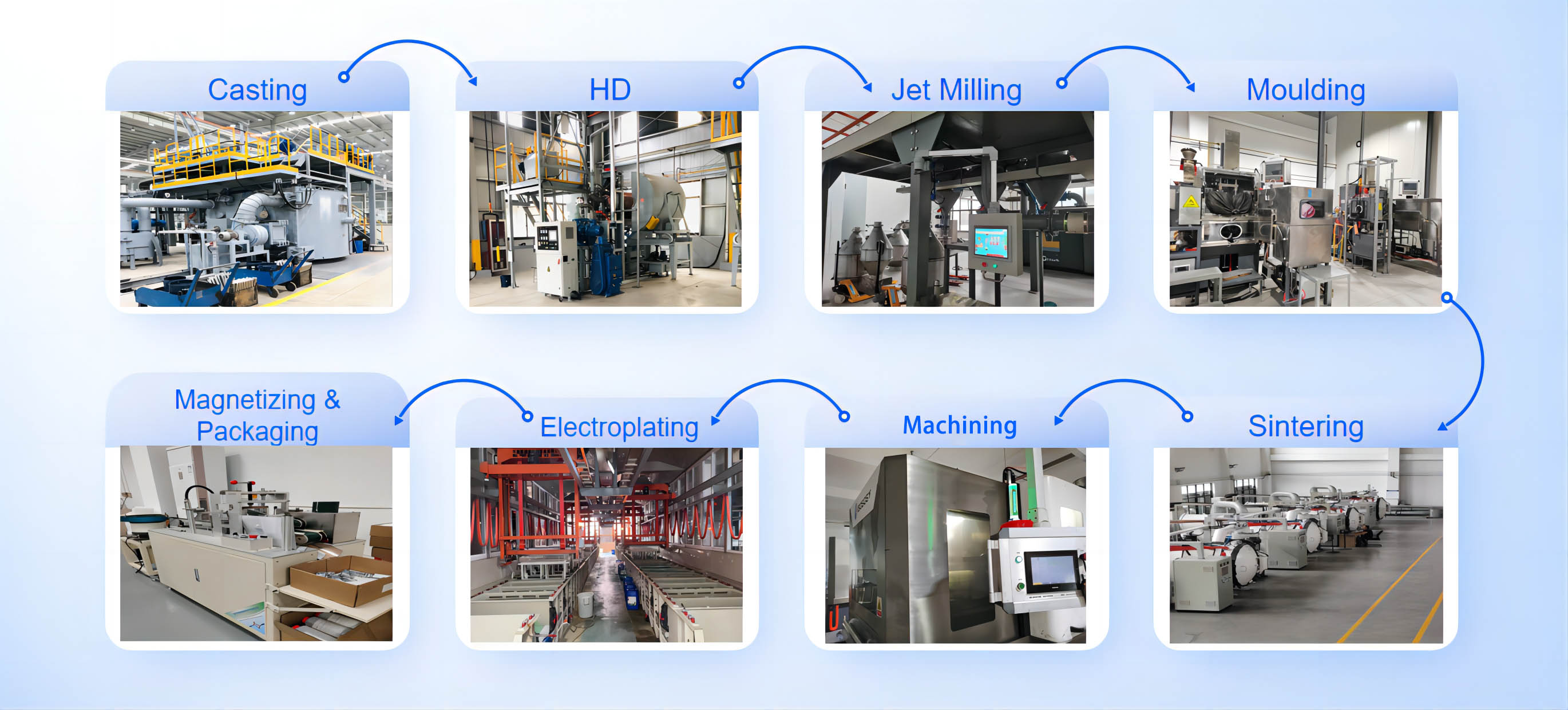

Mokhoa oa Tlhahiso ea NdFeB

Selelekela sa Coating

| Bokaholimo | Ho roala | Botenya μm | Mmala | Lihora tsa SST | Lihora tsa PCT | |

| Nickel | Ni | 10 - 20 | Silevera e Khanyang | > 24 -72 | > 24 -72 | |

| Ni+Cu+Ni | ||||||

| Nickel e Ntšo | Ni+Cu+Ni | 10 - 20 | Botsho bo kganyang | > 48-96 | > 48 | |

| Cr3+Zinc | Zn C-Zn | 5 - 8 | Brighe Blue Mmala o benyang | > 16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 - 25 | Silevera | > 36 -72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Khauta | >12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Silevera | >12 | > 48 | |

| Epoxy | Epoxy | 10 - 20 | Botsho/ Bohlooho | > 48 | --- | |

| Ke+Cu+Epoxy | 15-30 | > 72 ~108 | --- | |||

| Zn+Epoxy | 15-25 | > 72 ~108 | --- | |||

| Boikemisetso | --- | 1 - 3 | Boputsoa bo Lefifi | Tshireletso ya Nakwana | --- | |

| Phosphate | --- | 1 - 3 | Boputsoa bo Lefifi | Tšireletso ea nakoana) | --- | |

Litšobotsi Tsa 'Mele

| Ntho | Mekhahlelo | Boleng ba Reference | Yuniti |

| Magnetic e thusang Thepa | Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42–0,70 | %/℃ | |

| Mocheso o khethehileng | 0.502 | KJ·(Kg ·℃)-1 | |

| Mocheso oa Curie | 310~380 | ℃ | |

| Mechanical Physical Thepa | Botenya | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Ho hanyetsa Motlakase | 1.4x10-6 | μQ ·m | |

| Matla a Khatellang | 1050 | MPa | |

| Matla a tšepe | 80 | Mpa | |

| Matla a Kobehang | 290 | Mpa | |

| Thermal Conductivity | 6 ho isa ho 8.95 | W/m ·K | |

| Modulus ea Bacha | 160 | GPA | |

| Katoloso ea Mocheso(C⊥) | -1.5 | 10-6/℃-1 | |

| Katoloso ea Thermal(CII) | 6.5 | 10-6/℃-1 |

Pontšo ea Litšoantšo