Ts'ebeliso: E sebelisoa haholo mochining oa brushless motor, enjene ea masela e sa feleng, enjene ea masela, enjene ea koloi, enjene ea magnet direct drive motor, linear motor, air conditioning compressor motor, lisebelisoa tsa mochini tsa magnet motor, jenereithara ea Marine, jenereithara ea makenete e sa feleng, enjene ea magnet propulsion motor , enjene ea makenete e sa feleng ea meepo, enjene e kopanyang, enjene ea makenete e sa feleng ea lik'hemik'hale, koloi ea koloi bakeng sa EV, pompo ea koloi, EPS motor, sensor le libaka tse ling.

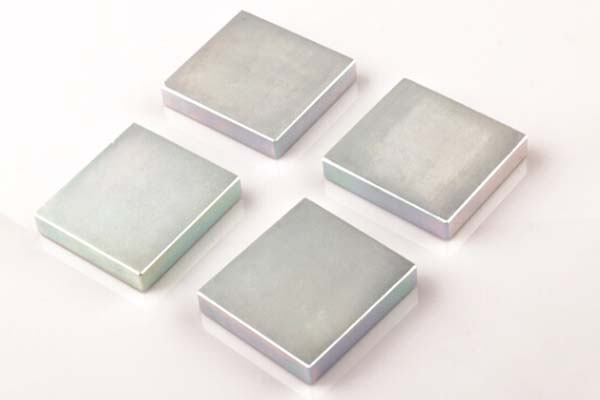

Sehlahisoa se hlophisitsoeng: makenete kaofela a hlophisitsoe, bolelele bo ka tloha ho 0.5mm-200mm, bophara ho tloha 0.5mm-150mm, botenya ho tloha 0.5mm-70mm, bo ka fihlelang tlhoko ea bareki ba bangata.

Coating: NdfeB makenete e bonolo ho oxidize, kahoo hangata e hloka ho roala, seaparo se tloaelehileng se sebelisoang 'marakeng joalo ka:

1. ZN plating (mofuta oa ho roala tšepe, tlhahlobo ea spray ea letsoai e ka fihla lihora tse 24-48, ts'ebetso ea theko e phahameng, kahoo ke e 'ngoe ea khetho e ntle ka ho fetisisa bakeng sa bareki ba bangata).

2. NICUNI (mofuta oa ho roala ka tšepe, tlhahlobo ea spray ea letsoai e ka fihla lihora tse 48-72, ts'ebetso ea litšenyehelo e phahametse ZN, empa e ntse e sebelisoa haholo 'marakeng boemo ba kopano bo thata, litlhoko tsa ho hanyetsa ho bola ha lihlahisoa tsa moreki li ka khona. khetha).

3. Epoxy (coat non-metallic, non-magnetic conductivity, e ka fokotsa tahlehelo ea hona joale ea motlakase, tlhahlobo ea spray ea letsoai e ka fihla lihora tse 72-96, theko e phahameng ho feta ZN ea NICUNI).

4. Ho roala tse ling tse neng li sebelisoa hape: Phosphate, Sn, Au, Ag, Parylene joalo-joalo...

Mamello: Hangata mamello ea rona ea makenete ke +/-0.05mm ka mor'a ho roala.

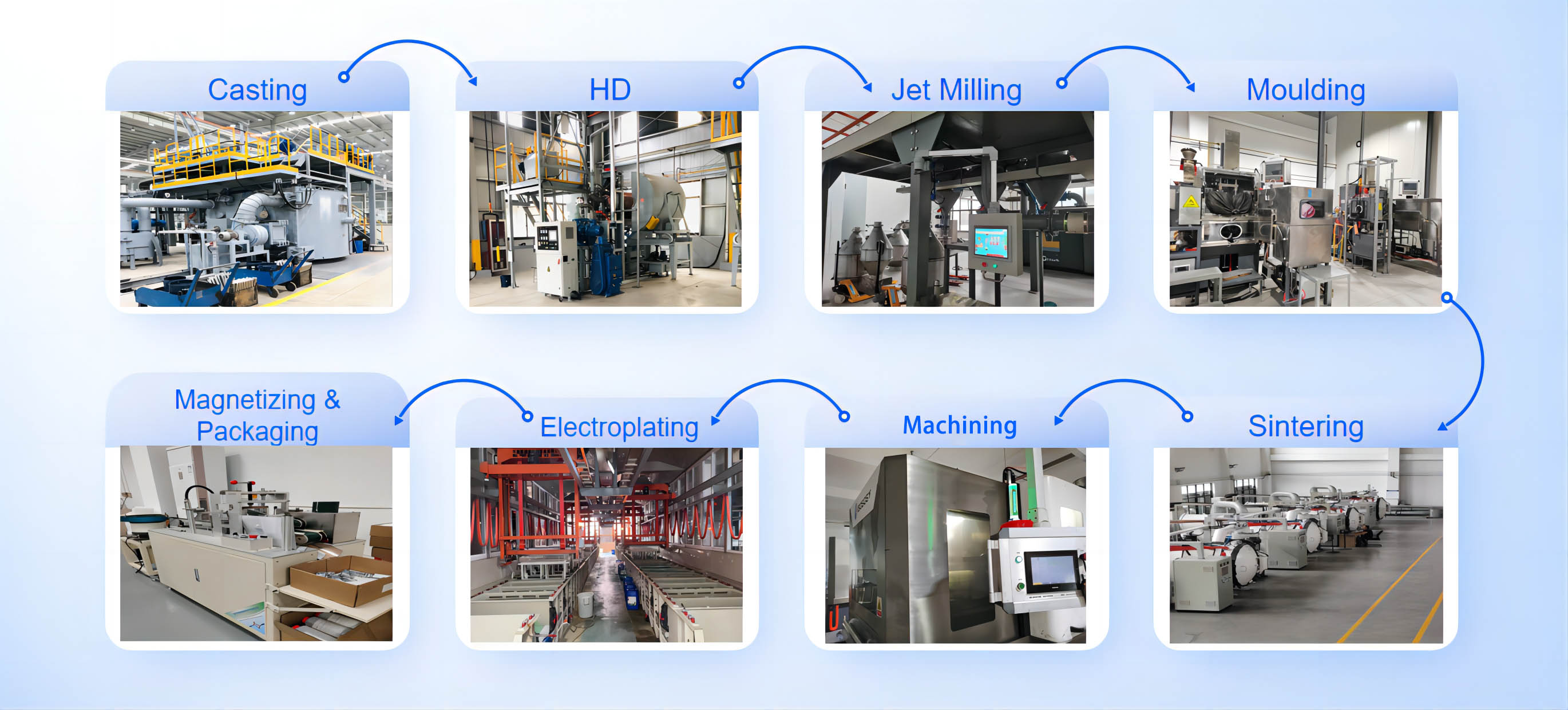

Mokhoa oa Tlhahiso ea NdFeB

Selelekela sa Coating

| Bokaholimo | Ho roala | Botenya μm | Mmala | Lihora tsa SST | Lihora tsa PCT | |

| Nickel | Ni | 10 - 20 | Silevera e Khanyang | > 24 -72 | > 24 -72 | |

| Ni+Cu+Ni | ||||||

| Nickel e Ntšo | Ni+Cu+Ni | 10 - 20 | Botsho bo kganyang | > 48-96 | > 48 | |

| Cr3+Zinc | Zn C-Zn | 5 - 8 | Brighe Blue Mmala o benyang | > 16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 - 25 | Silevera | > 36 -72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Khauta | >12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10-15 | Silevera | >12 | > 48 | |

| Epoxy | Epoxy | 10 - 20 | Botsho/ Bohlooho | > 48 | --- | |

| Ke+Cu+Epoxy | 15-30 | > 72 ~108 | --- | |||

| Zn+Epoxy | 15-25 | > 72 ~108 | --- | |||

| Boikemisetso | --- | 1 - 3 | Boputsoa bo Lefifi | Tshireletso ya Nakwana | --- | |

| Phosphate | --- | 1 - 3 | Boputsoa bo Lefifi | Tšireletso ea nakoana) | --- | |

Litšobotsi Tsa 'Mele

| Ntho | Mekhahlelo | Boleng ba Reference | Yuniti |

| Magnetic e thusang Thepa | Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42–0,70 | %/℃ | |

| Mocheso o khethehileng | 0.502 | KJ ·(Kg ·℃)-1 | |

| Mocheso oa Curie | 310~380 | ℃ | |

| Mechanical Physical Thepa | Botenya | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Ho hanyetsa Motlakase | 1.4x10-6 | μQ ·m | |

| Matla a Khatellang | 1050 | MPa | |

| Matla a tšepe | 80 | Mpa | |

| Matla a Kobehang | 290 | Mpa | |

| Thermal Conductivity | 6 ho isa ho 8.95 | W/m ·K | |

| Modulus ea Bacha | 160 | GPA | |

| Katoloso ea Mocheso(C⊥) | -1.5 | 10-6/℃-1 | |

| Katoloso ea Thermal(CII) | 6.5 | 10-6/℃-1 |

Pontšo ea Litšoantšo

-

Kenyelletso ea Isotropic le Anisotropic Ferrite

-

Bahoebi ba mabenkele a mahala ba Mohlala oa N52 Block Neod...

-

Lekola Mefuta e Fapaneng ea Limanete tsa Ferrite

-

Limagnete tsa boleng bo holimo tsa AlNiCo lia Fumaneha

-

Khetho e kholo bakeng sa Magnet e Matla ea Neodymium...

-

Ho sebelisa Round NdFeb ho Electroacoustic